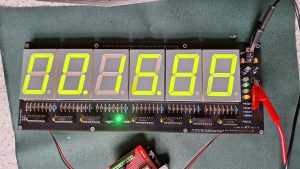

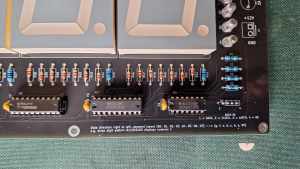

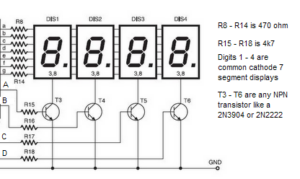

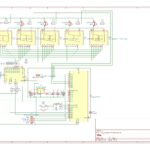

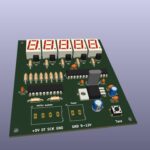

I have a couple of electronics projects in the works which use large LED displays and as they have a forward voltage of 8.4V and 20mA current they cannot be driven directly from a microcontroller using multiplexing. I could use a bunch of driver transistors or MOSFETS but that needs 14 pins on the microcontroller for a 6 digit display. So the reasonable option here is to use a chain of shift registers instead but the common 74HC595 is unable to drive the LED displays without external transistors. However there is the TPIC6B595 which has open drain outputs so can drive common anode displays and can sink up to 50V on each pin and at 500mA for the whole chip. Plenty to drive the 7 segment displays without multiplexing which is the solution I went for. Only 4 pins required on the microcontroller – yes technically only 3 for SPI but I wanted to control the Output Enable pin with PWM to adjust the display brightness.

The only problem is I’m wanting to build these projects for cheap and the TPIC6B595 is typically £10 each or £4.99 each on eBay. So I decided to take a risk and purchased 50 of them from a Chinese supplier on eBay who was advertising them as brand new for £3.96 for 10 plus £1.17 postage. That means for just less than £21 I’m getting them for £0.42 each. Bargain! Or not…?

Well they arrived after only 2 weeks via SpeedPak and I was immediately skeptical as to the description of “new”. On inspection most were obviously reclaimed parts as they were scratched, dirty and had a variety of date codes and font styles on the chip markings. The ones that did look new had a font completely different to the rest and no date code which later were found to have been blacktopped; a process where a chip is sanded down, painted and re-labelled. However despite all this on most of them the pins were in clean, good condition and none were bent so I’m assuming they were socketed in whatever device they were stripped from in the Chinese e-waste junkyard.

Skeptical, I made a test circuit that counted from 0-9 on a 7 segment display and to my surprise only 2 of them were dud. One of the duds was the suspected fake chip which *did* work in a fashion but upon powerup all of it’s outputs were on regardless of the OE pin logic level. It did go to normal once data was fed into it. The other had one output permanently shorted so it was always on. This looked like a genuine TI chip but it was obviously reclaimed as there was solder on the pins and part of the through hole plating of the PCB it was pulled from.

So, given the cost I got a bargain here. They were mis-advertised as “new” when they clearly were not but I wasn’t going to send them back and I gave the seller positive feedback, noting however they were not new parts. Having bought fakes before I’m always skeptical of cheap electronic components from eBay but I’m not complaining in this instance.

The seller I bought them from was cayin35 – I saved the seller and bought more parts such as IC sockets, resistors etc and these all turned out to be good.

Worth a look if you are wanting to save some money. I have no issues with buying parts like this as it re-uses parts that would otherwise end up in landfill or burnt saving the environment. A small drop in the ocean but every little helps right? If sellers were a bit more honest it would be better – maybe advertising them as used and tested? But if someone had to test them I guess that would put the cost up. But still, cheaper than UK suppliers.

Edit: due to me planning to sell some of my projects I purchased some genuine, new old stock chips from a UK supplier which worked out at around £2 per chip. These were fitted to two of the units I plan to sell on eBay and the reclaimed parts were used for the prototypes and future projects I’d be selling to friends and family.